Do you want to create a T-shirt that will stand out? Are you wondering which different types of t-shirt printing methods to use? There are many different options available, each with their own functions and uses. Here are the seven types of T-shirt printing methods to consider:

1. Screen Printing

This is one of the most popular t-shirt printing methods for professionals. Screen printing is also known as silkscreen printing. It guarantees a hundred percent reproduction of the design and is suitable for mass production of one colour printing.

It is done by creating a screen using a stencil and a nylon mesh. The nylon mesh is used to hold the stencil in place. Use waterproof material to block the negative space in your design. This should be the only part permeable. Now, flood the screen with ink. Your design should be replicated on the T-shirt.

2. Direct To Garments (DTG)

While screen printing is only suitable for simple designs, direct to garment printing works fine with complex designs. You need to be adequately skilled to apply this printing method. It works as a printer in the office would on printing paper. The garment takes the place of the printing paper. All you need is to upload your unique and creative design onto the computer.

This printing type is notable for the minimum quantity of ink applied. Your garment printer needs to be of good quality if you are to avoid low-resolution products. DTG works well on bright fabrics but performs poorly when it comes to durability.

3. Dye Sublimation

This is one of the fairly costly types of t-shirt printing methods. However, it produces superior products that are sharp and crisp. It works well when printing light T-shirts such as those made of polyester. It requires extensive knowledge of dye sublimation and printing machine handling. Many of the T-shirts you see out there with large designs spread all over are most probably products of the dye sublimation printing method.

A point of caution: do not try this method on cotton material. The result is usually horrible. The Special liquid used solidifies once it comes into contact with polyester. The process is culminated by the application of some heat to leave an imprint on your T-shirt permanently.

4. Heat Press Printing

This is an economical type of printing that is highly suitable for small orders. It is both cheap and takes less time to execute. The design is printed on a special material called transfer paper. Here’s how it works. Take a T-shirt, press it on the transfer paper (vinyl), then apply both heat and pressure. Wait till the heat softens the ink to the extent of reaching the cloth through the transfer paper.

Now take off the transfer paper and the dye. What you will end up with is a T-shirt with the exact design you intended. Heat press printing is ideal for complex durable designs on light coloured materials.

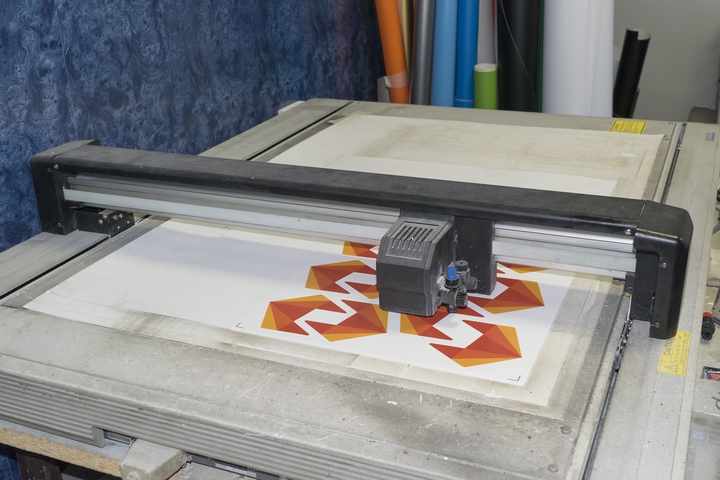

5. Vinyl Cutting

A printing type that uses a vinyl cutting machine to shape and design unique clothing. The shapes are then placed on a T-shirt using the heat press method. It has the advantage of being compatible with different types of cloth materials.

For these types of t-shirt printing, you can use a machine or adapt an iron box. Vinyl cutting is ideal for a business that deals with printing small graphics. Although durable and easy to apply, it is not suitable for large orders; and on materials that are sensitive to high heat levels.

6. Plastisol Transfer

Plastisol transfer has many similarities with screen printing, the only difference being that instead of transferring the ink to the screen, it is transferred to plastisol and then on to the T-shirt. Unless you are a seasoned printer, you may need to think about outsourcing some of the steps in plastisol transfer, especially in making the plastisol. All you need to do is come up with the designs, send them to the printer and let them ship the plastisol, which you can now apply using a heat press.

As in most heat-induced prints, plastisol transfer produces durable prints. This type of printing also produces high-quality work. However, transfers crack easily if due care is not observed. Large orders can also take a long time to fulfill, making them unsuitable for work with strict deadlines.

7. Computer-Aided Design Cut Printing

This is heat-related printing. CAD is suitable when printing numbers, logos, and names. For these types of t-shirt printing, the process involves transferring designs on fabric using heat. Create your designs on coloured vinyl with the help of the CAD-Cut system. After this, transfer these designs onto the fabric using a heat press. Computer-aided design is recommended for printing similar designs of up to 3 colours. It is durable, cost-effective for small runs, and can be applied onto any part of the T-shirt with ease.

When printing T-shirts, you want a method whose product is both aesthetically superior and whose process is adaptable to the cloth material you are using. It is also important to consider durability and cost-effectiveness.